Your benefits at a glance

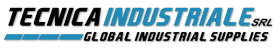

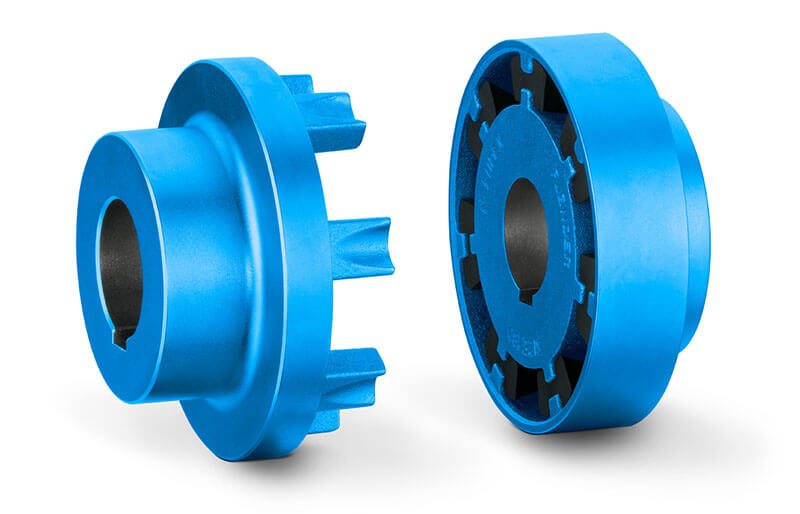

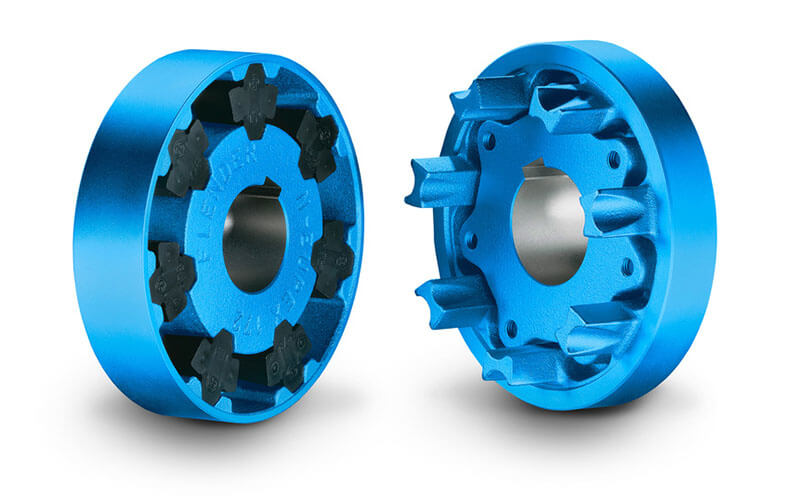

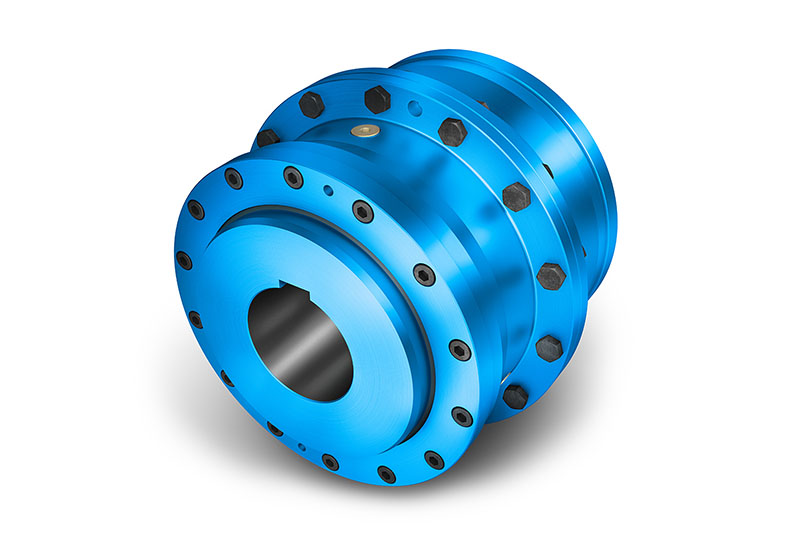

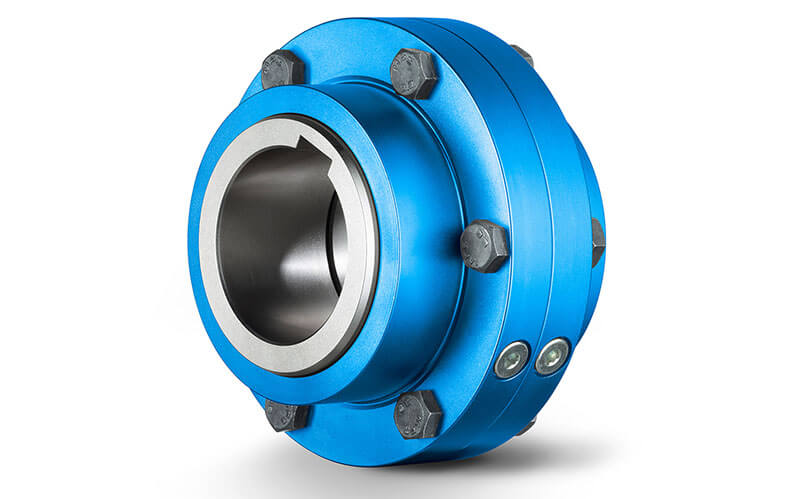

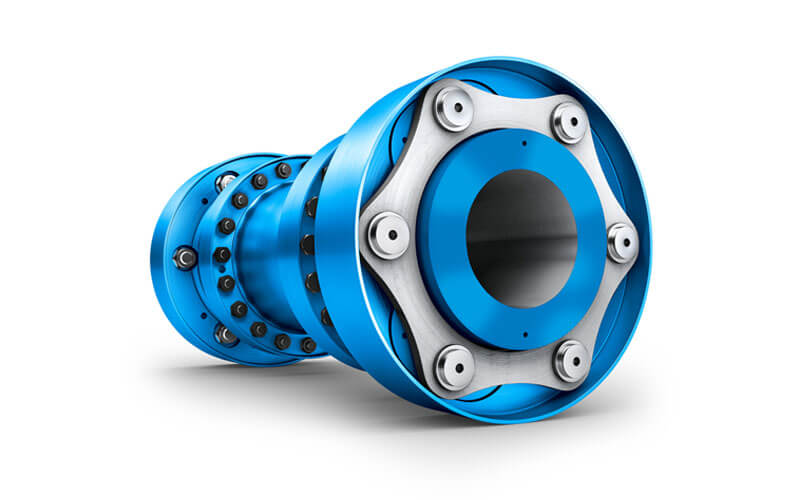

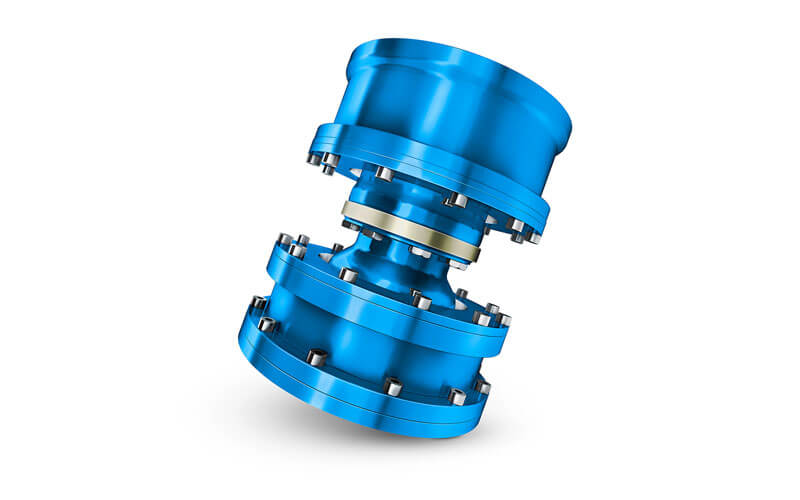

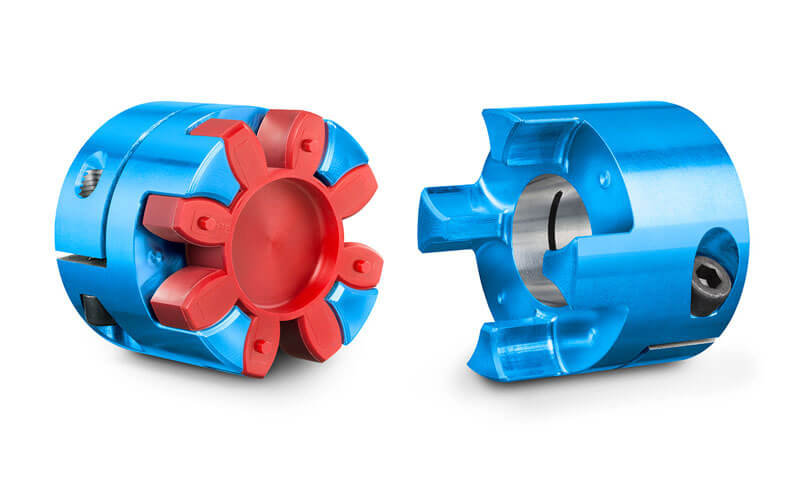

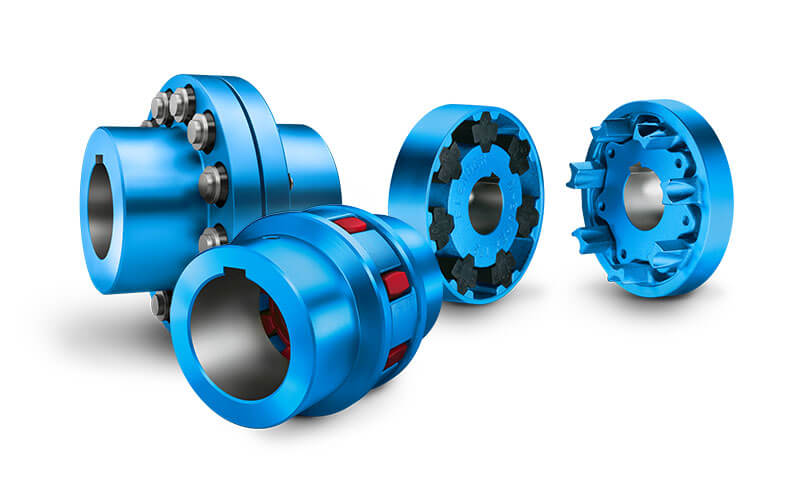

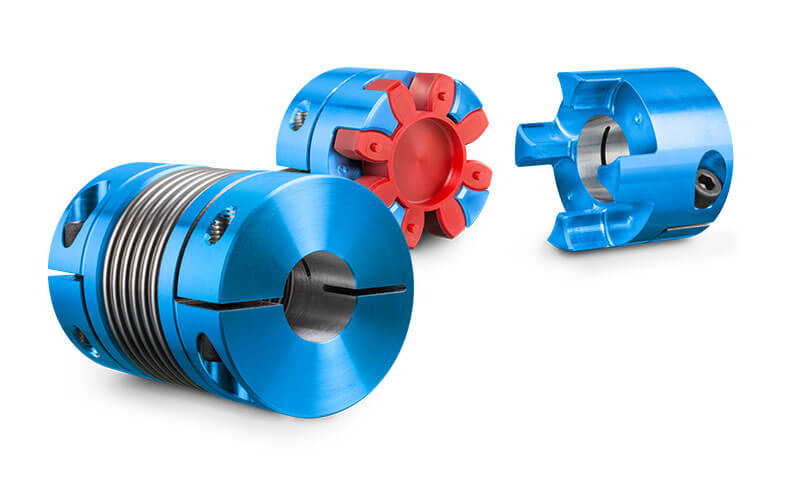

Compensation in angular, radial and axial shaft misalignment possible

Independent of the direction of rotation (suitable for reversing operation)

Torsionally rigid and free of circumferential backlash

Low restoring forces

Low-vibration (even with maximum permissible speeds)

Easy assembly through compact structural design

Conformity to API 610 and API 671

Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

Made in Germany, worldwide in use

Mining and Cement: conveyor belts, apron conveyors, bucket elevators, tube mills, bucket excavators, crushers, roller presses, separators, heating technology, slurry pumps

Steel Production: shears, reversing rolling mills, pilger rolling mills

Cranes: hoisting and luffing gear system, slewing gear systems, trolley and travel gear systems

Marine and Shipbuilding: single-engine ships, multi-engine ships, dredgers, generator gearboxes, installation vessels

Oil and Gas: installation vessels, pumps, fans, compressors, air condensers, jack-up rigs

Power Generation: air condensers, generators, gas turbines, cooling towers, water turbines, boiler feed pumps

Chemicals and Pharmaceuticals: driers, pumps and compressors, mixers, cooling towers, agitators, reactors

Plastics and Rubber: single- and double-screw extruders

Pulp and Paper: waste paper, wet section, dry section, smoothers and cylinders, reel winders, coating machines, calenders, wastewater purification plants

Water and Wastewater: aerators, water screw pumps

Food and Beverage: lauter tuns, reactors, agitators, mixer drives, filling systems

Sugar: generators, steam turbines, sugar cane mills

Railway Vehicles: railway couplings

Passenger Transport: cable cars

Other fields of application: test benches, wood milling, packaging machines